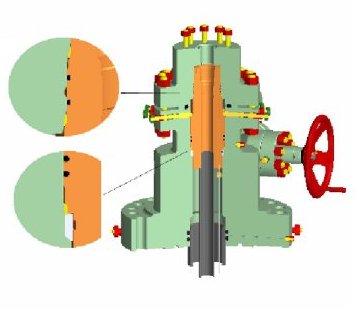

Full Metal Seal Completion Type FMS

This system is rated up to 20000 psi w.p. and it is practically unaffected by well fluid composition and high temperature. It is the most used solution when two metallic barriers between the well stram and production annulus are requested. The sealing system is based one Tubing Hanger body metal seal ring and on one or more upper metal seal ring/s on hanger extended neck.

Tubing Head Spool

The lower connection internal profile is designed to accept the production casing secondary seal that can be elastomeric seal or metal seal type.

The Tubing Head Spool can be provided with a Lock Nut to prevent thermal elongation of casing string.

An indipendent 45° shoulder is machined for Tubing Hanger suspension while another tapered surface is provided for T.H. annulus metal seal.

Tubing Hanger

The Tubing Hanger is machined from a solid bar with the extended neck prepared to accept two upper metal seal rings sealing Control Line passage and production bore.

The Tubing Hanger body annulus Metal Seal is energized by tubung weight and pressure load while metal seal on extended neck is energized by Tubing Head Adapter make up.